Climate-resilient robotic facades are emerging as a cutting-edge solution for addressing location-specific microclimate challenges in urban environments. Facade Today explores how this innovative approach combines advanced robotics with traditional brick construction to create adaptive building envelopes that respond dynamically to changing environmental conditions. Facade engineers and architects are at the forefront of integrating computer-aided microclimate simulation and robotic assembly technology to tailor brick patterns for specific urban contexts. By carefully analyzing factors such as solar radiation, wind patterns, and local climate data, facade engineers can optimize brick arrangements to create self-shading effects and improve thermal regulation. This data-informed design process pushes the boundaries of traditional facade design, enabling architects to create visually striking and highly functional building envelopes.

Thermal Guardians:

The Adaptive Power of Brick Facades

Urban areas face unique microclimate challenges, including the Urban Heat Island (UHI) effect, which significantly impacts thermal comfort and energy consumption. Each location presents distinct environmental conditions, such as varying levels of solar radiation, wind patterns, and humidity. To effectively address these challenges, facade engineers must consider detailed urban microclimate modeling, incorporating data on urban surface properties and morphologies.

The role of brick facades in thermal and airflow regulation

Brick facades play a crucial role in regulating thermal performance and airflow in buildings. The porosity and permeability of brick and masonry walls allow for air movement, which can contribute to natural ventilation and moisture management. Ventilated facade systems, incorporating brick elements, can enhance energy efficiency by creating an air chamber between the exterior cladding and the building’s insulation layer.

The thermal behavior of ventilated facades using perforated ceramic bricks has shown significant advantages over traditional facades, reducing air conditioning thermal loads. By tailoring brick patterns and arrangements, facade engineers can optimize the building’s response to specific microclimate conditions, enhancing thermal comfort and energy performance.

Advanced technologies, such as computer vision-based zero-shot learning paradigms, are now being employed to map facade materials with high fidelity. This enables more accurate assessment and design of climate-resilient facades, allowing for precise adaptation to local environmental challenges.

When Robotics Meets Sustainability

The Magic of Robotic Brick Patterns

Precision in bricklaying for optimized shading and ventilation

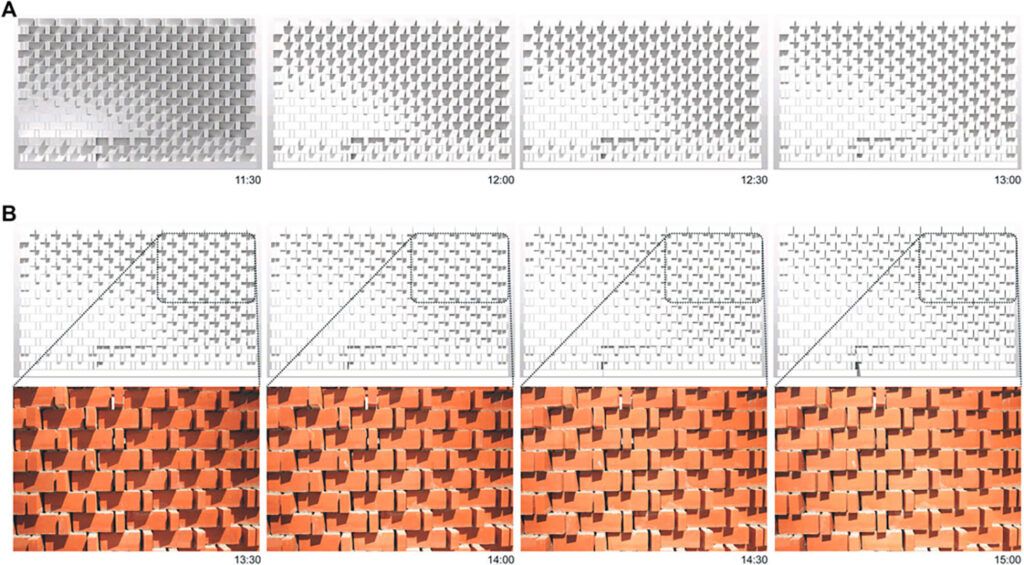

Robotic systems offer unparalleled accuracy in brick placement, allowing for the creation of complex geometries and patterns that would be challenging or impossible to achieve manually. This precision enables architects and engineers to design facades with intricate self-shading features, strategically positioned openings, and variable brick orientations. These elements work together to control solar radiation, enhance natural ventilation, and improve overall thermal performance of the building envelope.

Performance-Driven Design

Real-world applications of robotic brick facades have demonstrated significant benefits in energy efficiency, occupant comfort, and material optimization. These innovative structures leverage advanced computational design and robotic assembly techniques to create climate-responsive building envelopes tailored to specific microclimatic conditions.

Real-world Applications

A demonstrator object, measuring 2 m in height and 3 m in length, was constructed using a collaborative robot to showcase the potential of climate-resilient robotic facades 1. This project utilized a data-informed design process to create self-shading brick patterns optimized for local solar radiation profiles. The resulting structure exhibited reduced surface temperatures despite high solar exposure, validating the effectiveness of location-specific self-shading effects.

Measured Benefits

Thermal measurements on the built demonstrator revealed a maximum decrease in surface temperature of 4.7°C between the self-shading geometry and flat geometry sections of the wall. This significant temperature reduction contributes to improved thermal comfort for pedestrians at street level and potentially reduces cooling loads for the building.

In another study, an optimal brick facade design achieved an energy consumption of 94.6 kWh/m2, demonstrating the potential for substantial energy savings through performance-driven design 2.

Material Efficiency and Waste Reduction

Robotic assembly of brick facades offers precise control over material usage, significantly reducing waste. For instance, the RoboBrick® system can save up to 60% in raw materials and energy compared to traditional methods 3. The precision and accuracy of robotic systems in cutting and shaping materials further minimize material wastage, contributing to both cost savings and environmental benefits.

Integration with Circular Economy Principles

The integration of robotic brick facades with circular economy principles is an emerging area of focus. These systems can potentially incorporate recycled materials and optimize resource usage throughout the building lifecycle. By coupling parametric design with robotic assembly simulation, architects and engineers can now explore unlimited wall textures and configurations, optimizing for both aesthetic and performance criteria. This approach not only enhances the energy performance of buildings but also opens up new possibilities for architectural expression that responds dynamically to local environmental conditions.

(2) https://publications.ibpsa.org/proceedings/bs/2019/papers/BS2019_210904.pdf

(3) https://www.vandersanden.com/en-uk/robobrickr-industrial-facade-system

Useful links:

https://www.frontiersin.org/journals/built-environment/articles/10.3389/fbuil.2022.856871/full

Case studies:

Musée Yves Saint Laurent Marrakech (2017)

Architects: Studio KO

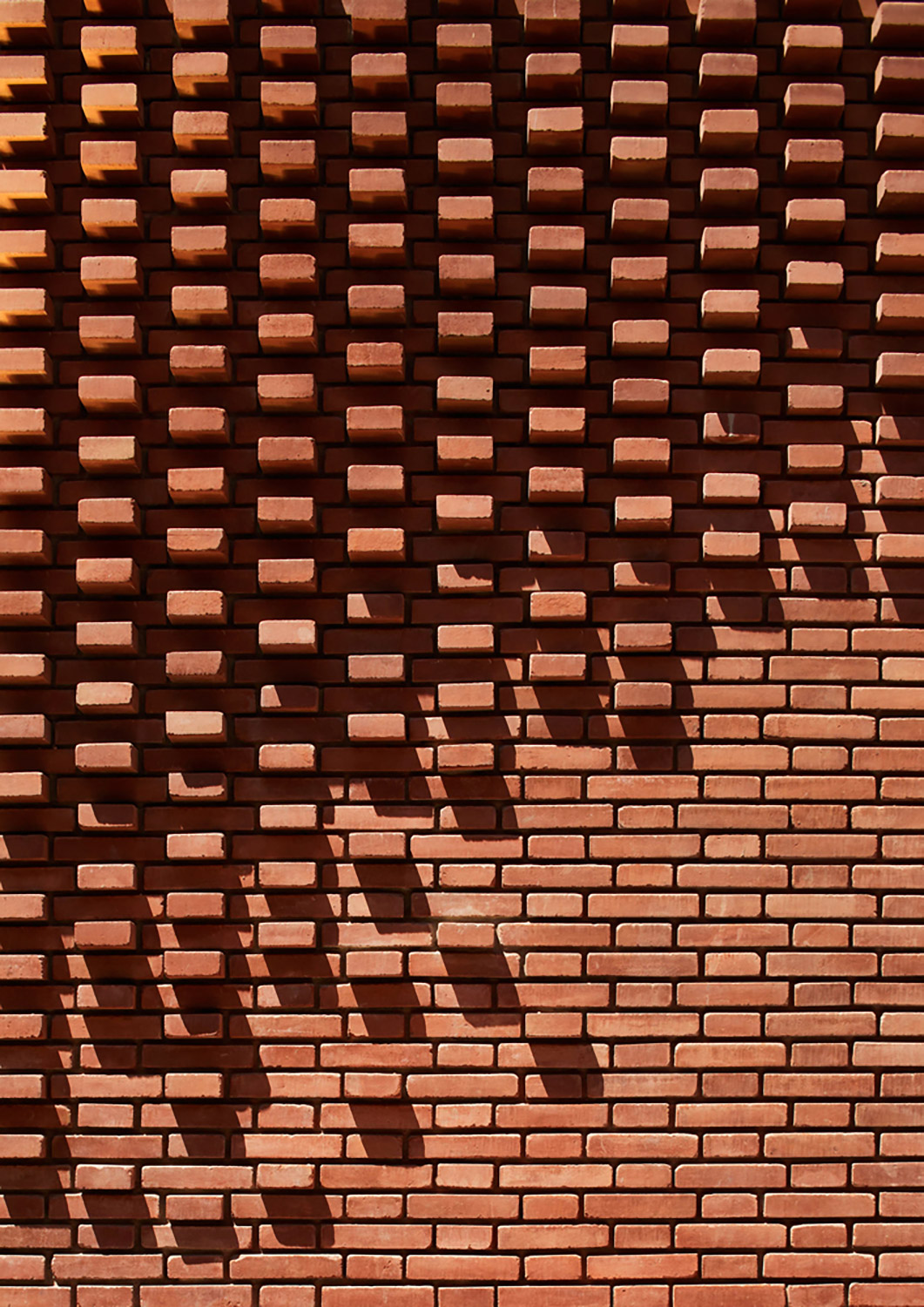

The Musée Yves Saint Laurent Marrakech, designed by Studio KO and opened in 2017, exemplifies innovative use of brick patterns to create a dynamic facade that responds to local climate conditions. The building’s exterior features an intricate arrangement of terracotta bricks, forming a lace-like covering that evokes the weft and warp of fabric. This design not only pays homage to Saint Laurent’s work but also serves a functional purpose. The brick pattern creates a play of light and shadow across the facade, changing throughout the day as the sun moves. This self-shading effect helps regulate the building’s temperature in Marrakech’s hot climate. The architects used locally-sourced terracotta bricks and Moroccan earth, integrating the museum harmoniously with its surroundings. The contrast between the textured exterior and the smooth, luminous interior mirrors the construction of a haute couture jacket, reflecting the museum’s content in its very architecture.

Augmented Bricklaying, Kitrus (Greece, 2019)

Client: KITRVS Winery / Garypidis

Dynamic optical guidance: Gramazio Kohler Research, ETH Zurich

https://gramaziokohler.arch.ethz.ch/web/e/projekte/371.html

The Kitrvs winery in Greece showcases a groundbreaking application of augmented bricklaying, combining computational design with traditional craftsmanship. Completed in 2019, this project features a 225m² façade composed of 13,596 individually placed bricks, each precisely rotated and tilted to create an intricate, semi-transparent pattern. The design, derived from a Perlin noise field, produces an ever-changing façade resembling shimmering light on liquid.

The brick pattern’s complexity serves both aesthetic and functional purposes. Gaps between bricks allow for ventilation and control sunlight penetration, while the varied mortar heights and brick rotations create a dynamic play of shadows across the façade. This innovative approach not only enhances the building’s visual appeal but also demonstrates the potential of augmented reality in architectural construction, bridging the gap between advanced digital design and skilled manual labor.

As the Editor of FacadeToday.com, I merge my passion for Design, Architecture and Technologies with three decade of experience collaborating with entrepreneurs across many industries. My career has centered on fostering innovation, scaling business opportunities, and bridging gaps between technical experts, business developers, and creative visionaries. I thrive at the intersection of sustainable solutions, material advancements, and smart technologies, curating insights on themes like energy-efficient facades, smart tech, and advanced manufacturing. With a commitment to lifelong learning, I aim to empower architects and facade engineers by translating innovations into actionable knowledge, driving the industry forward through purposeful connectivity and cutting-edge practices.