Moisture intrusion presents one of the most critical challenges in facade engineering, as even minor flaws in the building envelope can lead to leaks, persistent condensation, and compromised insulation performance. Facade waterproofing is essential because it protects key interfaces from water ingress and long-term moisture accumulation. When moisture penetrates a facade system, whether through insufficient waterproofing or poor detailing, the risks extend well beyond surface staining or aesthetic defects. Persistent dampness can foster hidden mold growth, degrade structural components, undermine thermal comfort, and escalate maintenance costs. Furthermore, mold is particularly concerning for health, as spores circulating indoors may trigger allergic reactions and respiratory problems for occupants. Effective moisture control and facade waterproofing are thus fundamental not only for occupant wellness and asset preservation, but also as pillars of sustainable architecture. In this article Facade Today explores this increasingly important topic, guiding facade professionals on how well-sealed, moisture-resistant facades can advance both building health and sustainable practice.

Cracks, Gaps, and Weak Spots

The Moisture Infiltration Map

Moisture infiltration originates from a variety of sources, each posing unique risks to structural integrity and indoor environmental quality. Rain penetration remains a primary threat; water can seep through poorly sealed joints, interfaces around windows, and roof connections, especially during driving rain events or under wind pressure. Over time, aging seals, cracks in cladding, or deteriorated flashing enable even small amounts of water to bypass protective layers and cause cumulative damage. Vapor diffusion can lead to hidden condensation inside wall assemblies, particularly when insulation or vapor barriers are incorrectly installed. Plumbing leaks and internal water sources, such as HVAC equipment or water pipes within facade cavities, further contribute to moisture load and complexity, requiring vigilant inspection and prompt repairs.

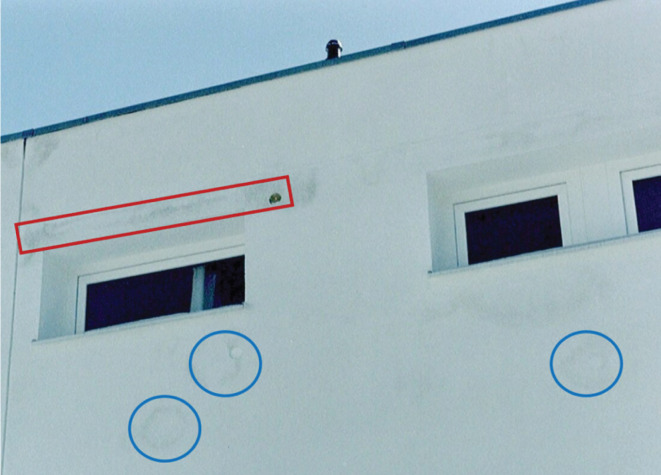

Facade weak points are typically found at the intersections: joints between different materials, window perimeters, roof-wall interfaces, and penetrations for mechanical or electrical systems. These areas are highly susceptible to leaks and condensation and demand robust detailing and regular maintenance.

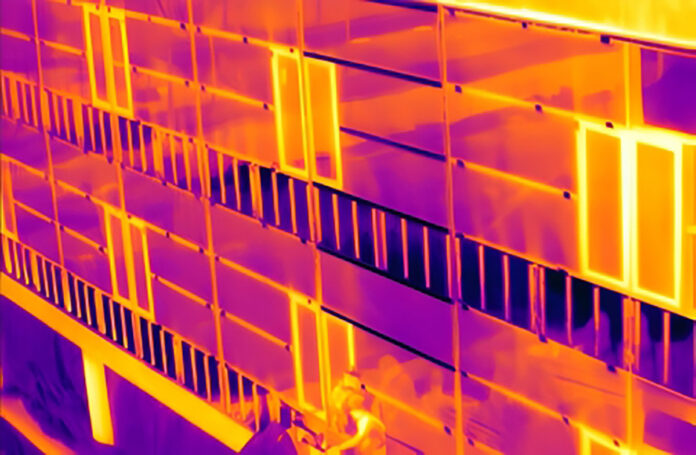

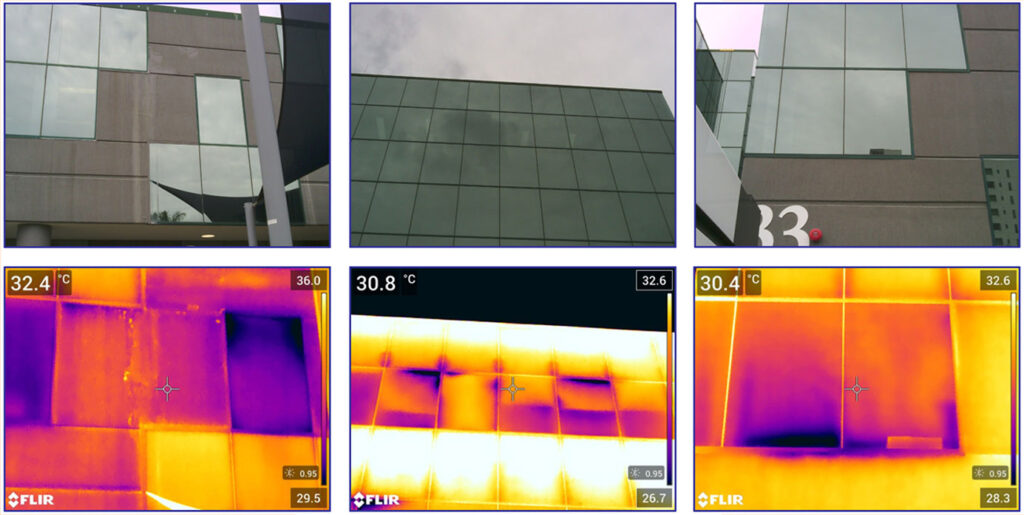

Advanced diagnostic technologies such as infrared thermography and moisture mapping enable non-destructive identification of moisture anomalies inside building envelopes. These tools visualize hidden leaks, insulation voids, and areas at risk for condensation, providing quantitative data to guide effective remediation and long-term moisture management. By employing thermal imaging cameras, resistance-based sensors, and data loggers, facade waterproofing professionals can pinpoint sources of water intrusion, verify the extent of dampness, and optimize facade maintenance strategies to prevent mold and material degradation.

Understanding Condensation Hotspots

Condensation within facades is frequently the result of thermal bridging, where heat transfer through poorly insulated structural components causes surface temperatures to drop below the dew point, allowing moisture in the air to condense into liquid. This is particularly common at window frames, metal fasteners, and other conductive elements. Calculating the dew point for various facade layers and ensuring that insulation and vapor barriers are correctly placed are essential for reducing condensation risk. Persistent condensation encourages mold growth and can degrade insulation, finishes, and structural components, requiring comprehensive design strategies and diligent execution during construction and operation.

Blueprint for Health

Facade Waterproofing Safeguarding Wellness

Effective facade waterproofing and moisture control begins with rigorous attention to the interface areas, joints, penetrations, window perimeters, and connections between dissimilar materials, all of which are vulnerable paths for air and water ingress. Detailing should prioritize continuous air and water barriers, using high-quality sealants and gaskets appropriate for each substrate. Silicone-based sealants excel on non-porous surfaces like glass and metal, while polyurethane or acrylic sealants offer strong adhesion to porous materials such as concrete or masonry. Field installation quality is upheld through methodical inspection, with particular scrutiny of seal continuity at critical locations such as corners, parapets, and window surrounds. Tools such as blower doors, smoke pencils, and infrared cameras help assess airtightness, while water spray testing detects leaks in real-world conditions. Regular visual checks of sealants for cracks, peeling, or weathering enable timely repairs before small breaches escalate.

The Moisture Control Playbook for Resilient Facades

Moisture control must be woven into the design workflow from the earliest project stages. Architects, facade engineers, and consultants should collaborate to detail robust water-management strategies, including rainscreens, drainage paths, and compatible vapor barriers tailored to the building’s location and use. Design documentation should specify approved materials, tested assemblies, and clear performance targets reflecting current codes and anticipated climate trends. Specifications should be treated as living documents, revised as new risks or solutions emerge. Interdisciplinary design reviews help anticipate constructability challenges, e.g., conflicts between insulation depth and air barrier placement, or between access for maintenance and continuous defense layers. Early contractor involvement can further ensure that intent translates into reality and that field crews understand both the critical details and the consequences of shortcuts.

Sealing Success: Inspection, Maintenance, and Remediation Strategies

A high-performing facade waterproofing strategy depends on continued vigilance. Periodic assessment protocols, visual surveys, sealant testing, infrared scans, and targeted moisture meters, support early detection of leaks, condensation, and hidden mold. It’s essential to focus inspections on high-risk elements, such as window perimeters, joints between systems, and areas experiencing dynamic movement. Early interventions, including prompt resealing, cleaning weep holes, and addressing minor cracks, can prevent extensive water and mold damage. Notable case studies consistently demonstrate the value of proactive maintenance such as regular reapplication of water-repellent treatments or scheduled joint renewal to extend facade service life and protect occupant health. With structured inspection, building owners not only maintain performance but also reinforce their commitment to sustainable, healthy built environments.

Tiny Tech, Big Impact: Harnessing Tech to Lock Out Moisture

Emerging technologies are transforming facade waterproofing and how building professionals manage moisture risks and mold growth in facade systems. Smart sensors, now integrated directly into key facade elements, continuously monitor leak-prone zones and hidden cavities for signs of unwanted humidity or water infiltration. By providing real-time alerts, these IoT-enabled devices empower rapid intervention, minimizing mold risk and enabling data-driven decisions for maintenance teams.

Nanomaterials and bio-based coatings represent another leap forward, delivering high-performance barriers that repel moisture, inhibit microbial colonization, and adapt to evolving building standards with sustainability in mind. These coatings often deploy microscopic structures that block water ingress while allowing vapor diffusion, or use biobased chemistry to actively break down organic contaminants.

Data analytics platforms now tie these innovations together: by aggregating sensor data from across a building or portfolio, facility managers can pinpoint emerging moisture risks, predict the likelihood of condensation and mold, and automate routine inspections based on measured trends.

From Wet Walls to Wellness Advancing Healthier Architectural Solutions

Future directions in facade waterproofing and moisture control are shaped by tightening regulations, demand for energy efficiency, and the adoption of smart, resilient materials. Trends such as rainscreen cladding, prefabricated panels, open-joint ventilated facades, and digital monitoring systems are driving new standards in facade performance and durability. Continued research into advanced barriers, sensor integration, and biobased or recycled products presents valuable opportunities for industry and academia to collaborate. By doing so, the building envelope community can deliver healthier, more sustainable, and longer-lasting facades for the future.

Useful links

https://www.sciencedirect.com/science/article/abs/pii/S2352710221002497

As the Editor of FacadeToday.com, I merge my passion for Design, Architecture and Technologies with three decade of experience collaborating with entrepreneurs across many industries. My career has centered on fostering innovation, scaling business opportunities, and bridging gaps between technical experts, business developers, and creative visionaries. I thrive at the intersection of sustainable solutions, material advancements, and smart technologies, curating insights on themes like energy-efficient facades, smart tech, and advanced manufacturing. With a commitment to lifelong learning, I aim to empower architects and facade engineers by translating innovations into actionable knowledge, driving the industry forward through purposeful connectivity and cutting-edge practices.