Glass is a cornerstone material in modern facade systems, prized for its transparency, durability, and aesthetic versatility. However, its production and end-of-life disposal present significant environmental challenges. Glass recycling offers a pathway to address these issues, yet the manufacturing of architectural glass remains energy-intensive, requiring high temperatures that result in substantial carbon emissions. Additionally, raw material extraction and transportation further contribute to the industry’s environmental footprint.

When glass facades reach the end of their service life, they are often demolished and sent to landfills. This linear approach not only wastes valuable material but also exacerbates resource depletion and environmental degradation. Glass is non-biodegradable, and its accumulation in landfills poses long-term ecological risks.

In this article, Facade Today explores the challenges and opportunities of glass recycling in facade systems, highlighting how circular design can foster more sustainable solutions.

Glass with a Second Life:

Benefits of Glass recycling for Modern Facades

Recycling and reusing glass in construction offer a compelling solution. By incorporating recycled glass – known as cullet – into new facade components, manufacturers can significantly reduce energy consumption, as cullet melts at lower temperatures than raw materials. This process also curtails greenhouse gas emissions and conserves natural resources such as sand, soda ash, and limestone.

Beyond environmental benefits, glass recycling supports the principles of the circular economy by extending material life cycles and minimizing waste. Reusing glass in facade systems can inspire innovative design approaches, promote resource efficiency, and help the industry meet increasingly stringent sustainability targets. Embracing glass recycling is not only an environmental imperative but also a strategic opportunity for facade engineers, architects, and developers to lead the way in sustainable building design.

From Waste to Worth:

Evolving Practices and Persistent Challenges in Facade Glass Recycling

Glass recycling in facade systems is gaining traction as the construction industry embraces circular economy principles. The typical recycling process involves collecting post-consumer or post-industrial glass, cleaning and sorting it by color and composition, crushing it into cullet, and then melting and reforming it into new glass products.

In façade projects, reclaimed glass is increasingly used for secondary glazing, decorative panels, and even structural elements. Notable examples include commercial buildings that incorporate recycled glass panels or curtain walls made from high-percentage recycled content, demonstrating both aesthetic and environmental benefits.

Challenges in Glass recycling of Facade Components

Despite these advancements, several challenges hinder widespread glass recycling in facade systems. Technically, modern facade glass often features coatings, laminates, or is part of hybrid assemblies (such as insulated glass units), complicating separation and recycling. The presence of adhesives, interlayers, and embedded hardware further impedes efficient disassembly.

To address these issues, some glass manufacturers have taken proactive steps by organizing the collection of used glass from facades themselves. In some cases, manufacturers collect entire window or curtain wall frames and separate the materials in-house, ensuring better control over the separation process and higher-quality recycled glass. Others collect only glass fragments directly from demolition or renovation sites, but this approach risks contamination and offers less control over material purity.

Logistical and economic hurdles persist. Collecting and transporting used facade glass can be costly, especially when contamination or breakage occurs. The fluctuating market demand for recycled glass and the lack of standardized recycling infrastructure pose additional obstacles.

Finally, regulatory and market limitations-such as inconsistent recycling policies, building codes, and limited incentives-restrict the adoption of recycled glass in new construction. Overcoming these challenges will require coordinated efforts across design, manufacturing, and policy sectors to unlock the full potential of glass recycling in circular facade design.

Opportunities for Circular Design

The Glass Comeback

As sustainability becomes a priority in construction, glass is making a comeback—not just as a material, but as a cornerstone of circular design. Below, we explore key strategies and real-world examples that are shaping the future of circular facades.

Design for Disassembly and Modularity

Circular facade systems begin with design. Modular glass units, secured with mechanical fasteners instead of adhesives, enable easy disassembly and reuse. For example, prefabricated panels with standardized dimensions allow components to be replaced or upgraded without dismantling entire facades.

Innovations in Glass Processing and Reuse

Advanced technologies are overcoming recycling barriers. Laser cleaning removes coatings without harming the glass, while chemical treatments efficiently separate laminates. These advances ensure that more glass can be recovered and reused, supporting a true circular economy.

Closed-Loop Recycling and Cullet Streams

Collaborations between manufacturers and recyclers are creating closed-loop systems. For instance, AGC Glass Europe has launched the ‘AGC Recycle Glass’ service, which collects old flat glass from demolition and modernization projects, processes it into high-quality cullet, and reincorporates it into new flat glass production. This initiative is part of their broader closed-loop recycling strategy for facade and window glass 1. Saint-Gobain Glass also operates a closed-loop recycling program, collecting post-consumer glass and re-manufacturing it into new glass products at their Eggborough facility in the UK 2.

Strategies for Scaling Glass Recycling

Policy and Industry Collaboration:

Governments can set minimum recycled content requirements—like France’s RE2020—while industry groups such as the Circular Facades Alliance drive standardization and innovation.

Developing Recycling Infrastructure:

Local recycling hubs near cities reduce transport emissions. The UK’s “Glass Recovery Zones” boosted facade glass recycling rates by 35% in just two years.

Standardization and Certification:

Certifications like Cradle to Cradle and ISO 14021 verify recycled content quality. Digital material passports track glass composition, making future reuse simpler and more reliable.

Conclusion

The future of glass recycling in facade systems is promising, driven by emerging technologies such as advanced glass separation, laser-based de-coating, and digital material passports that streamline recycling and reuse. Trends like modular facade design and closed-loop manufacturing are setting new standards for circularity, while policy initiatives and industry collaborations are accelerating adoption.

By equipping the next generation of facade experts with circular economy principles, knowledge of material cycles, design for disassembly, and sustainable sourcing, the industry can create buildings that are both innovative and regenerative.

On their end, architects, engineers, and developers are encouraged to champion circular design, specify recycled glass, and participate in knowledge-sharing networks. By doing so, the facade industry can lead the way toward a truly sustainable built environment.

(2) https://www.saint-gobain-glass.co.uk/sustainability/glass-forever/

Case studies

UNESCO V, Paris, France (2024)

Architects: Patriarche

Facade engineers: Eckersley O’Callaghan

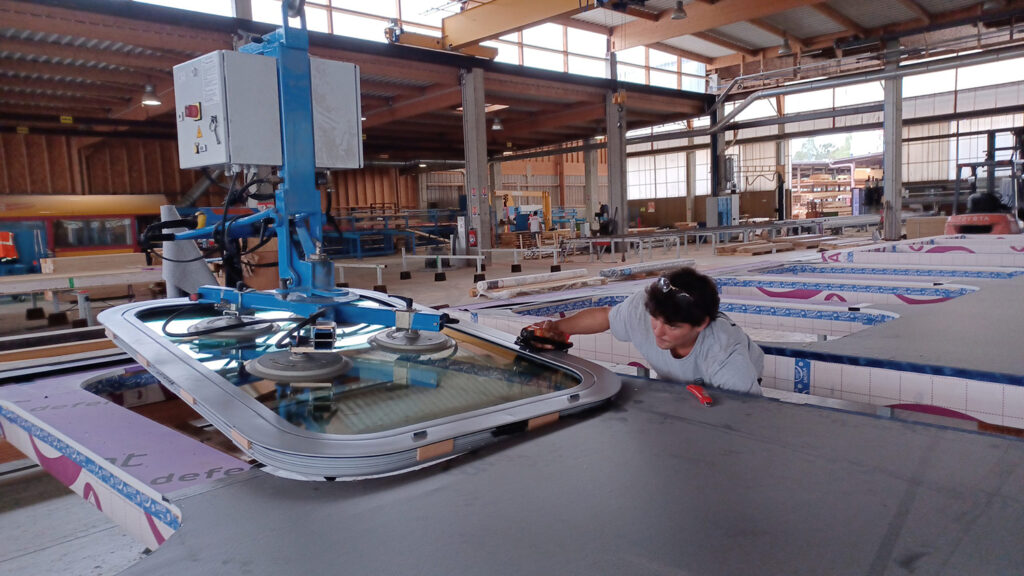

Facade module manufacturing: Concept-MOB

The UNESCO V project in Paris, designed by Patriarche with facade engineering by Eckersley O’Callaghan and module manufacturing by Concept-MOB, stands as a pioneering example of glass recycling in modern facade construction. The project prioritized the reuse of original cladding and the recycling of monolithic glass panels. Existing glass was carefully dismantled, processed into cullet by Ares, and remelted by Saint-Gobain for new low-carbon facade panels. By reusing cullet, the project supports circular design principles and demonstrates how innovative glass recycling can be seamlessly incorporated into high-performance building envelopes. The UNESCO V project not only achieves remarkable aesthetic results but also sets a benchmark for combining sustainability, resource efficiency, and architectural excellence in urban development.

1 Triton Square, London, UK (2021)

Architects and Facade Engineers: Arup

At 1 Triton Square, Arup led a pioneering circular economy refurbishment, reusing over 3,500 m² of facade glass panels. The panels were carefully dismantled, transported to a pop-up factory less than 30 miles away, deep cleaned, refurbished, and fitted with new gaskets before being reinstalled. This process, enabled by dry-fixed connections and detailed as-built records, avoided the carbon emissions of new glass production and saved 2,400 tonnes of CO₂. The approach set a new benchmark for sustainable commercial retrofits and achieved BREEAM Outstanding certification.

As the Editor of FacadeToday.com, I merge my passion for Design, Architecture and Technologies with three decade of experience collaborating with entrepreneurs across many industries. My career has centered on fostering innovation, scaling business opportunities, and bridging gaps between technical experts, business developers, and creative visionaries. I thrive at the intersection of sustainable solutions, material advancements, and smart technologies, curating insights on themes like energy-efficient facades, smart tech, and advanced manufacturing. With a commitment to lifelong learning, I aim to empower architects and facade engineers by translating innovations into actionable knowledge, driving the industry forward through purposeful connectivity and cutting-edge practices.

We try and reuse and recycle the cullet in our architectural glass projects, but getting hold of the glass is often a problem. Maybe we need a national glass recycling database?

Completely agree. The bottleneck isn’t the will to use cullet, it’s access and traceability. A glass‑recycling database with regional collection points, spec info (coatings, laminates, contaminants), and best practices for dismantling architectural glass during building renovations, could massively improve supply for architectural projects. Until then, it’s frustrating to see so much good material still treated as waste.

By the way, you have beautiful references in architectural glass art at Boha Glass. Congrats!