Computational Fluid Dynamics (CFD) has become an indispensable tool in the field of facade engineering, empowering designers and engineers to analyze and optimize the performance of building envelopes with unprecedented precision. Facade Today explores how CFD simulations are transforming the way professionals predict building responses to environmental forces such as wind, solar radiation, and temperature gradients.

By simulating airflow, heat transfer, and pressure distribution around and within facades, CFD provides critical insights for ensuring occupant comfort, energy efficiency, and structural integrity. In ventilated facades, for example, CFD can quantify the cooling effect of air movement, reducing reliance on mechanical systems and enhancing sustainability. As facade systems grow more complex, CFD offers a robust, data-driven foundation for informed decision-making throughout the design and construction process.

The Power of CFD Simulations

Unlocking Facade Performance

Continuous performance improvement in facade engineering is about more than just achieving initial design targets; it involves ongoing evaluation and optimization to adapt to changing environmental conditions, occupant needs, and technological advancements. CFD plays a pivotal role in this iterative process by enabling engineers to conduct “what-if” analyses, test alternative solutions, and validate performance under a range of scenarios. By integrating CFD into the design workflow, teams can identify potential issues – such as thermal bridging, wind-driven rain infiltration, or inadequate ventilation – before construction begins, reducing risks and costs. Furthermore, post-occupancy CFD studies allow for the monitoring and fine-tuning of facade performance, ensuring that buildings continue to meet or exceed their operational goals throughout their lifecycle.

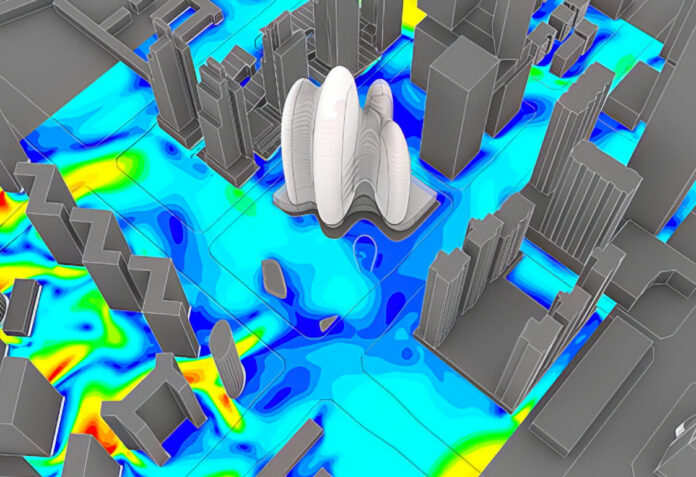

CFD uses numerical methods and algorithms to solve and analyze problems involving fluid flows. By discretizing the fluid domain into small elements, CFD software calculates variables such as velocity, pressure, and temperature throughout the system, providing detailed visualizations and quantitative data. This capability allows engineers to simulate real-world conditions and predict how fluids – such as air or water – will interact with solid surfaces, such as building facades.

Key Parameters for Facade Applications

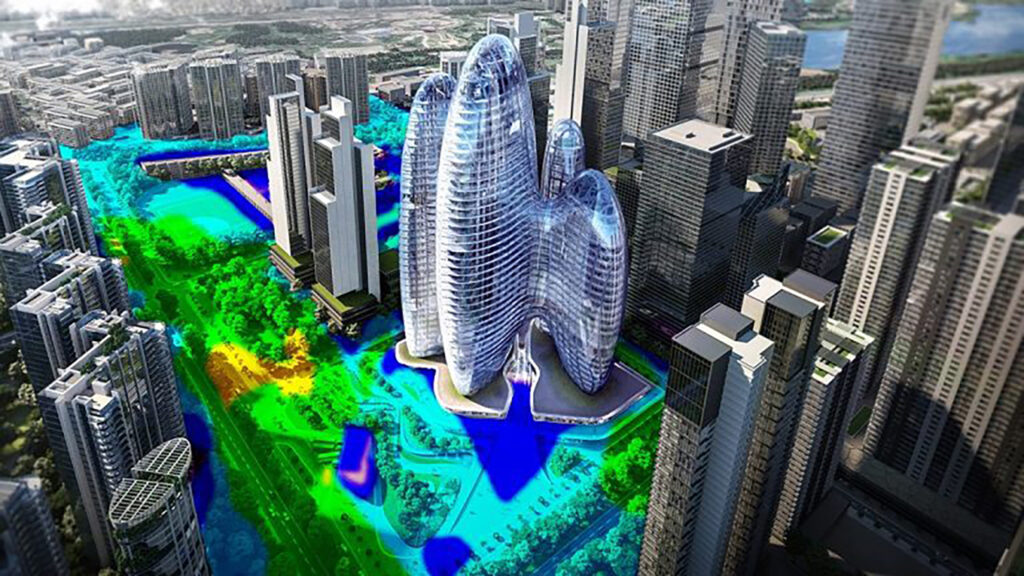

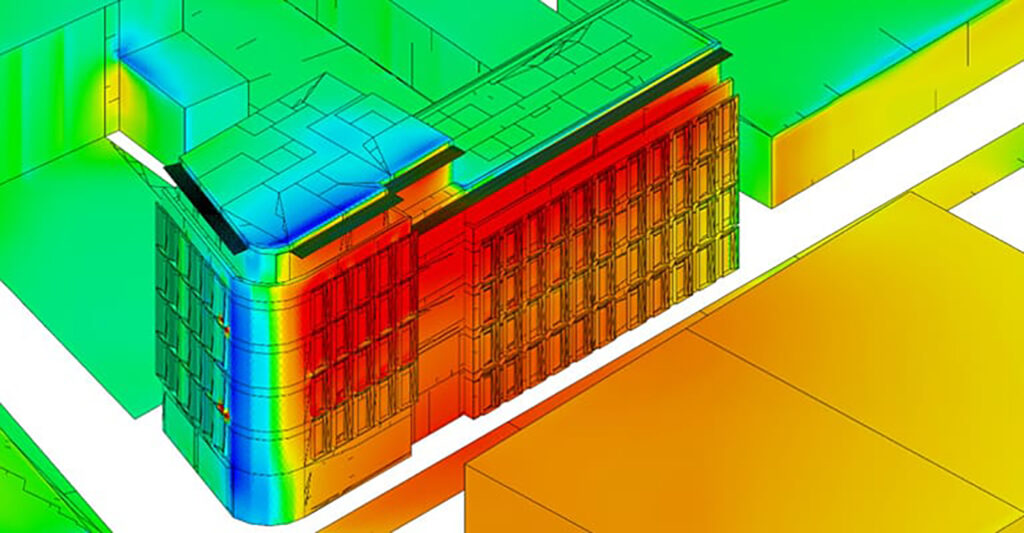

In facade engineering, CFD simulations typically focus on several key parameters: airflow patterns, temperature distribution, pressure differentials, and heat transfer rates. These parameters help engineers assess natural ventilation effectiveness, thermal comfort, wind load resistance, and energy efficiency. For example, in ventilated facades, CFD can model the velocity and temperature of air within the cavity, revealing how design choices impact cooling performance and moisture management. By understanding these relationships, engineers can optimize facade geometry, material selection, and construction details to achieve superior performance and sustainability.

Mastering Microclimates

Applications of CFD simulations in Facade Innovation

CFD simulations are transforming facade engineering by enabling precise analysis of complex environmental interactions. Three core applications stand out: thermal performance analysis, wind load assessment, and natural ventilation optimization.

Thermal Performance Analysis

CFD allows engineers to model heat transfer through facade assemblies, including the effects of solar radiation, conduction, and convection. For example, simulations can assess the effectiveness of ventilated facades in reducing cooling loads, as air gaps between cladding and insulation create convective currents that lower surface temperatures and enhance thermal comfort. By analyzing temperature distributions and heat fluxes across different facade configurations, CFD helps identify hotspots and optimize insulation strategies for maximum energy efficiency.

Wind Load Assessment

Accurate prediction of wind pressures is crucial for both safety and cost efficiency, especially in tall or complex buildings. CFD provides detailed pressure maps across the facade, enabling engineers to assess local wind loads and identify areas prone to excessive stress or vibration. This is particularly valuable for designing resilient cladding systems and ensuring structural integrity under diverse weather conditions. CFD simulations can also replace or complement wind tunnel tests, offering flexibility and cost savings in early design stages.

Natural Ventilation Optimization

CFD is instrumental in designing facades that promote natural ventilation, reducing reliance on mechanical systems. By simulating airflow patterns around and within buildings, engineers can evaluate the effectiveness of window placements and other ventilation features. CFD helps visualize air movement, identify stagnant zones, and optimize openings for cross-ventilation and stack effect, ensuring healthy indoor environments and energy savings.

CFD simulations and CFD-Driven Design:

Shaping the Future of Facades

Effective use of CFD requires embedding simulations early in the design process. Parametric modeling and BIM integration allow for rapid iteration and comparison of facade options. By generating digital twins of proposed facades, teams can test various scenarios and validate performance before construction.

Successful facade design depends on close collaboration between architects and engineers. CFD results provide a common language for discussing performance trade-offs, such as aesthetics versus energy efficiency or ventilation versus wind resistance. Post-construction, CFD can be used to monitor facade performance and identify opportunities for improvement.

Navigating the Hurdles:

Overcoming CFD Challenges

While CFD integration offers significant potential for facade engineering, the field faces considerable challenges that limit widespread adoption. High-fidelity simulations require substantial computational resources, which often puts these advanced tools beyond the reach of smaller firms. Furthermore, turbulence modeling presents ongoing difficulties: traditional Reynolds-averaged Navier-Stokes (RANS) methods struggle to accurately capture complex airflow patterns around building facades, yet the alternative large eddy simulations (LES) demand computational power that remains impractical for routine design work. Adding to these technical hurdles, validating CFD results against real-world performance proves challenging due to constantly changing environmental conditions and the current absence of standardized validation protocols across the industry.

In conclusion, integrating CFD into design workflows requires interdisciplinary collaboration, which many teams lack due to siloed expertise or insufficient training. Recent advances in AI and machine learning are streamlining CFD workflows, cutting simulation times and improving accuracy in turbulence modeling. Meanwhile, standardized validation frameworks – such as wind tunnel benchmarking and sensor-aided post-occupancy monitoring – are enhancing the reliability of CFD results. Finally, simplified interfaces and automated tools are making CFD more accessible to non-specialists, fostering greater collaboration between architects and engineers.

Useful links:

https://www.azobuild.com/article.aspx?ArticleID=8724

https://link.springer.com/article/10.1007/s12273-023-1052-y

Case studies

Howard One, Nottingham, UK (2024)

Architects: AM2 Architects

CFD simulations: Simscale

AM2 Architects faced the challenge of accurately assessing overheating risk in a naturally ventilated student accommodation building in Nottingham city center. While traditional thermal modeling tools provided broad estimates for regulatory compliance, they struggled to capture the complex wind pressure profiles affecting natural ventilation. To address this, SimScale’s cloud-based CFD platform enabled detailed simulations of wind flow around the building, accounting for local terrain, neighboring structures, and real-world atmospheric conditions. The CFD results—wind pressure coefficients (Cp)—were integrated into their thermal model, leading to a more accurate prediction of airflow and indoor comfort. This approach revealed that airflow rates could double compared to standard methods, reducing summertime peak temperatures by 2°C and transforming the building’s overheating risk assessment from a regulatory fail to a pass.

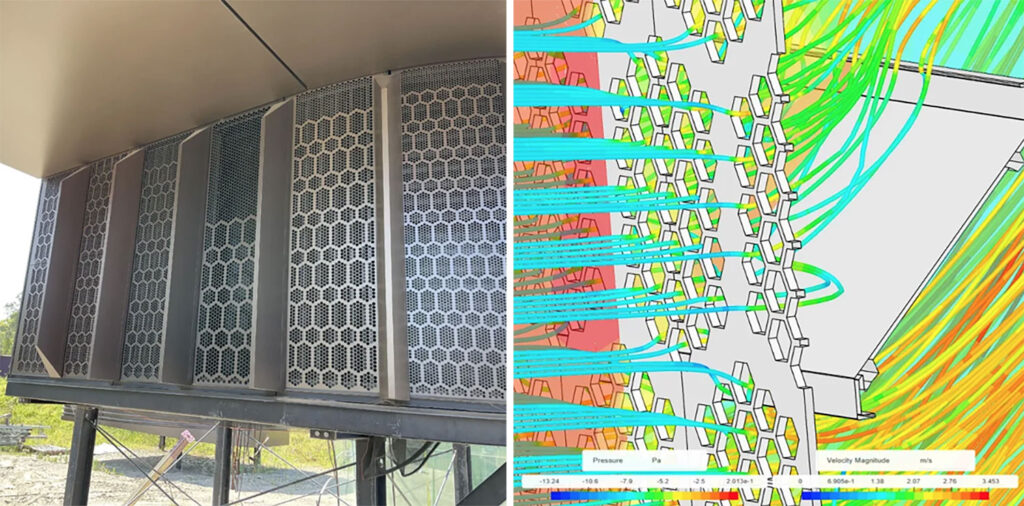

Parkline Place, Sydney, Australia (2024)

Architects: Foster + Partners

Executive architect: COX Architecture

Facade engineering: Fairlite Consulting

CFD simulations: Simscale

Fairlite engineers delivered a high-performance facade for the Pitt St. Metro Station in Sydney, designed by Foster + Partners, blending architectural ambition with energy efficiency. Dedicated plant room floors required robust ventilation, traditionally addressed with mechanical louvers – an approach at odds with Foster & Partners’ vision for sleek, perforated screens. Fairlite leveraged advanced CFD analysis to accurately model airflow and pressure drop through both mechanical louvers and architectural screens. This enabled innovative designs that concealed louvers behind visually striking facades while minimizing material use. Validated against AS 4740-2024 physical tests with less than 2% error, CFD replaced costly physical testing, saving $30,000 AUS in physical testing. The approach empowered precise component sizing and ensured compliance, demonstrating how CFD drives creative, cost-effective, and high-performance facade engineering.

As the Editor of FacadeToday.com, I merge my passion for Design, Architecture and Technologies with three decade of experience collaborating with entrepreneurs across many industries. My career has centered on fostering innovation, scaling business opportunities, and bridging gaps between technical experts, business developers, and creative visionaries. I thrive at the intersection of sustainable solutions, material advancements, and smart technologies, curating insights on themes like energy-efficient facades, smart tech, and advanced manufacturing. With a commitment to lifelong learning, I aim to empower architects and facade engineers by translating innovations into actionable knowledge, driving the industry forward through purposeful connectivity and cutting-edge practices.