Facade engineers and architects are leveraging Lotus Effect technology to create self-cleaning, low-maintenance building exteriors. By specifying and integrating materials that mimic the lotus leaf’s superhydrophobic surface structure, they implement coatings and surfaces that repel water and dirt, reducing cleaning needs and extending facade lifespans. This innovation enhances building durability, energy efficiency, and sustainability. It also opens new possibilities for smart, multifunctional facades, potentially incorporating embedded sensors and energy-harvesting capabilities in future designs.

Superhydrophobicity

How Lotus Leaves Inspire Innovative Facades

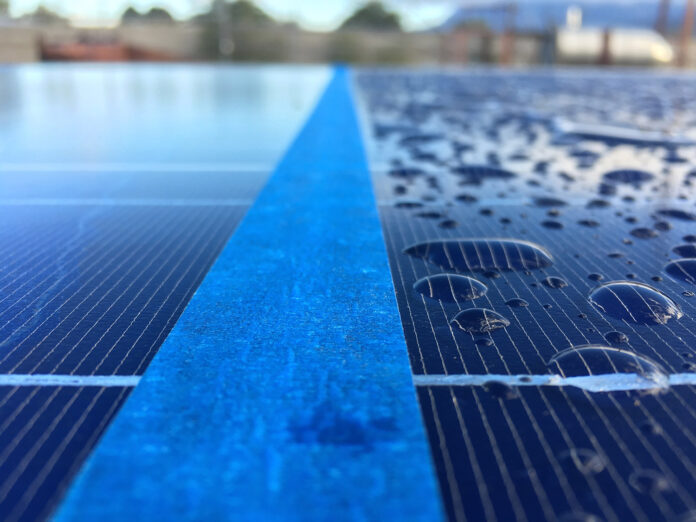

The lotus effect refers to the self-cleaning properties exhibited by lotus leaves, characterized by superhydrophobicity and a unique surface structure. This phenomenon arises from a combination of micro and nano-scale surface features and a hydrophobic wax coating. Lotus leaves possess a hierarchical surface structure with micro-scale mounds covered in nano-scale hair-like protrusions. This roughness, combined with the hydrophobic epicuticular wax layer, creates a superhydrophobic surface with a contact angle exceeding 150°.

Water droplets on lotus leaves form near-perfect spheres due to minimal surface contact. As they roll off, they collect dirt particles, effectively cleaning the surface.

Material Innovation:

Scientists have developed various methods to mimic the lotus effect, creating self-cleaning surfaces for applications ranging from building materials to textiles:

- Nanotechnology is used to produce surfaces with micro/nano structures that replicate the lotus leaf’s topography.

- Low surface energy materials, such as fluorinated compounds, are used to create hydrophobic coatings that enhance water repellency and self-cleaning properties.

Cleaner Facades, Lower Costs

The Economic Advantage of Self-Cleaning Surfaces

Lotus Effect technology has found numerous applications in facade engineering, revolutionizing the way buildings interact with their environment.

Exterior paints and coatings incorporating Lotus Effect properties have become increasingly popular. These coatings create a superhydrophobic surface that repels water and contaminants, keeping building exteriors clean with minimal intervention. Rainwater effectively washes away dirt and debris, maintaining the facade’s appearance and integrity over time.

Self-cleaning windows are another significant application. By applying Lotus Effect nanotechnology to glass surfaces, windows remain clearer for longer periods, reducing the need for manual cleaning. This is particularly beneficial for high-rise buildings or structures with difficult-to-access glazing.

Corrosion-resistant surfaces have been developed using Lotus Effect principles, protecting metal components of facades from environmental degradation. This technology is especially valuable in coastal or industrial areas where corrosion is a significant concern.

Performance Benefits

The implementation of Lotus Effect surfaces in facades offers several key benefits:

Reduced maintenance costs are a primary advantage. Self-cleaning properties significantly decrease the frequency of cleaning operations, lowering labor and equipment costs associated with facade maintenance.

Enhanced durability and longevity are achieved as these surfaces resist degradation from environmental factors. By minimizing the accumulation of corrosive substances and reducing water penetration, facades maintain their structural integrity for longer periods.

Improved energy efficiency is an often-overlooked benefit. Cleaner surfaces, especially in glazing, allow for better light transmission and thermal performance. This can lead to reduced heating and cooling loads, contributing to overall building energy efficiency.

The Science Behind the Shine

Nanostructures in Action

Nanotechnology plays a crucial role in producing Lotus Effect self-cleaning coatings. These coatings are typically created using sol-gel processes, which allow for the formation of nanostructured surfaces at low temperatures. Advanced techniques like X-ray lithography and photolithography are employed to create precise micro- and nanopatterns on surfaces.

Quality control and consistency are ensured through various methods. Atomic force microscopy (AFM) is used to examine surface morphology and verify the presence of the desired nanostructures. X-ray Photoelectron Spectroscopy (XPS) helps analyze coating composition and correlate it with performance metrics like static water contact angle.

For large-scale production, manufacturers focus on scalability, with some coatings being fully scaleable from liters to barrel. Customization capabilities allow for adaptation to different project sizes and substrate materials. Ongoing research aims to improve durability and weatherability, with some coatings now able to withstand up to 3000 hours of xenon arc exposure.

Smart and Sustainable

The Circular Economy of Self-Cleaning Facades

Lotus Effect self-cleaning surfaces offer significant sustainability benefits, primarily through reduced cleaning chemical use. Traditional facade maintenance often involves harsh detergents and large volumes of water, which can have negative environmental impacts. Self-cleaning surfaces minimize the need for these cleaning agents, reducing chemical runoff and water consumption. This not only decreases the environmental footprint of building maintenance but also lowers operational costs over time.

The extended lifespan of facades incorporating Lotus Effect technology contributes to circular economy principles. By maintaining their appearance and functionality for longer periods, these surfaces reduce the frequency of repairs and replacements. This longevity translates to reduced material consumption and waste generation over the building’s lifecycle, aligning with sustainable construction practices.

Future Developments

The future of Lotus Effect surfaces in facade engineering is promising, with ongoing research into smart coatings with embedded sensors. These advanced materials could potentially monitor environmental conditions, detect pollutants, or even assess their own cleaning efficiency. Such real-time data could optimize building management systems and further reduce maintenance needs.

Another exciting development is the combination of self-cleaning properties with other functionalities. Researchers are exploring ways to integrate Lotus Effect surfaces with energy-harvesting technologies, such as transparent solar cells for windows. This multi-functional approach could result in facades that are not only self-cleaning but also energy-generating.

Additionally, there’s potential for combining self-cleaning properties with air-purifying capabilities. Photocatalytic materials that break down air pollutants could be incorporated into Lotus Effect coatings, creating facades that actively contribute to improving urban air quality while maintaining their cleanliness.

These advancements promise to elevate the role of facades from passive building elements to active contributors to sustainability and smart city initiatives.

Useful links:

https://phys.org/news/2016-06-lotus-leaf-scientists-world-self-cleaning.html

https://lotus-nano.com/sustainable-solar-energy-production-with-nanotech

As the Editor of FacadeToday.com, I merge my passion for Design, Architecture and Technologies with three decade of experience collaborating with entrepreneurs across many industries. My career has centered on fostering innovation, scaling business opportunities, and bridging gaps between technical experts, business developers, and creative visionaries. I thrive at the intersection of sustainable solutions, material advancements, and smart technologies, curating insights on themes like energy-efficient facades, smart tech, and advanced manufacturing. With a commitment to lifelong learning, I aim to empower architects and facade engineers by translating innovations into actionable knowledge, driving the industry forward through purposeful connectivity and cutting-edge practices.

![Schematic illustration of the "self-cleaning" concept. A water droplet rolling off on (a) a lotus leaf surface and (b) on a smooth solid surface. When a droplet lands on the surface, the particle succumbs to the dominant capillary forces and attaches to the droplet rather than the surface. As a result, it is removed along with the rolling water droplet [Ghasemlou M, Daver F, Ivanova E P and Adhikari B 2019 J. Mater. Chem. A 7 16643–16670].](https://facadengineering.com/wp-content/uploads/2025/03/Self-cleaning-concept-lotus-effect.jpg)