Modern buildings require facade materials that withstand environmental stressors while maintaining structural integrity and visual appeal. Traditional concrete, though strong and versatile, is prone to cracking from thermal expansion, shrinkage, and mechanical stress. These cracks reduce durability and safety, increase maintenance costs, and raise the carbon footprint due to frequent repairs. As sustainable construction becomes a priority, the industry is seeking solutions to extend facade lifespan and minimize maintenance. Self-healing concrete offers a breakthrough in facade engineering, enabling autonomous crack repair and restoring integrity without external intervention. Facade Today explores self-healing concrete as a game-changing solution in facade engineering.

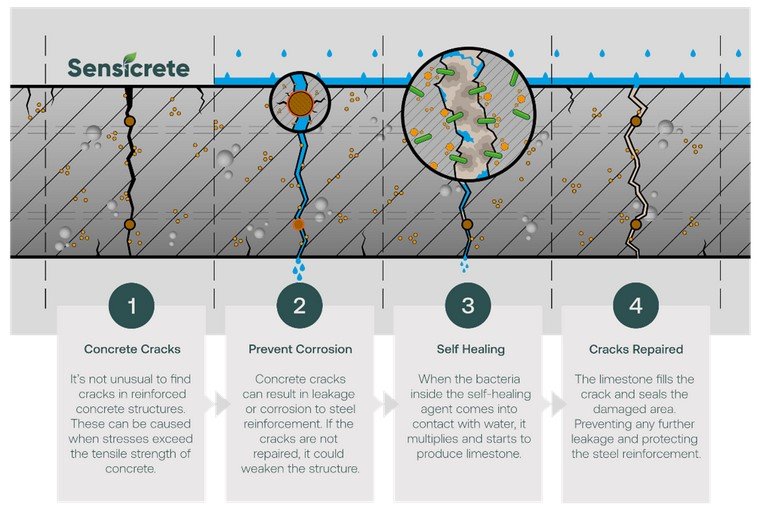

The self-healing technology operates through several mechanisms, including autogenous healing (using unhydrated cement particles), biological healing (utilizing bacteria to precipitate minerals), and chemical healing (embedding microcapsules or vascular networks with healing agents). When cracks form, these agents are activated – either by water ingress or mechanical stress – releasing substances that fill and seal the damaged areas. Notably, microcapsule and vascular self-healing systems have shown promise for accurately targeting and repairing cracks, while biological approaches offer sustainable, eco-friendly benefits. By integrating self-healing concrete into facade systems, engineers and architects can significantly enhance durability, and reduce lifecycle costs. They will contribute to more sustainable building practices.

From Microcracks to Marvels

Mechanisms of Self-Healing Concrete

Self-healing concrete employs both autogenous and autonomous mechanisms to repair cracks, significantly extending the lifespan of facades. Autogenous healing relies on the natural hydration of unreacted cement and the precipitation of calcium carbonate when water enters microcracks. However, this process is limited to very fine cracks (typically less than 150 μm) and requires the presence of moisture.

To address larger or recurring cracks, innovative autonomous systems are integrated into concrete mixtures. These include capsules, fibers, or vascular networks loaded with healing agents that are released when cracks occur. Among the most promising self-healing agents are:

Bacteria: Certain Bacillus species are encapsulated in microcapsules or lightweight aggregates. When activated by water infiltrating a crack, these bacteria precipitate calcium carbonate, effectively sealing the fissure and restoring durability.

Superabsorbent Polymers (SAPs): These polymers are hydrogels capable of absorbing and retaining large amounts of water relative to their own mass. When incorporated into concrete, SAPs swell upon contact with water, physically blocking cracks. They provide internal curing that enhances further healing through continued hydration and mineral precipitation.

Encapsulated Polymers: Microcapsules containing polymeric or chemical healing agents rupture when cracks form, releasing their contents to bond and seal the crack faces 1.

Innovative Concrete Mixtures

Recent advances focus on optimizing the compatibility and longevity of these healing agents within the cement matrix. For example, encapsulation techniques have improved the survival and activation of bacteria, while SAPs are now engineered for pH sensitivity and controlled swelling. Comparative studies show that self-healing concrete can achieve equal or greater compressive strength and significantly improved durability compared to conventional mixes, especially in terms of reduced water absorption and maintenance needs. These innovations position self-healing concrete as a transformative material for sustainable, low-maintenance facades.

(1) https://pmc.ncbi.nlm.nih.gov/articles/PMC9106089/

From Durability to Integration

Game-Changing Benefits and Real-World Challenges

Self-healing concrete significantly extends the lifespan of facades by autonomously repairing cracks that develop over time. This self-repair capability maintains structural integrity, and prevents the ingress of water and corrosive substances. It also protects internal reinforcement from corrosion, resulting in more durable and resilient building envelopes.

By automatically sealing cracks, it minimizes the need for frequent manual repairs and maintenance interventions. Studies indicate maintenance costs can be reduced by up to 50% over a structure’s life cycle. This not only lowers operational costs. It also reduces disruptions associated with traditional repair methods, such as scaffolding, labor, and downtime that can impact building occupants. Over time, the reduction in maintenance activities translates to fewer resources spent on inspections, repairs, and material replacements. For building owners and facility managers, this means greater predictability in budgeting for upkeep and a lower total cost of ownership. Additionally, the improved reliability and reduced risk of unexpected failures contribute to safer, more resilient building operations.

Beyond durability and cost savings, self-healing concrete also delivers important environmental benefits. It reduces the demand for new materials, repair products, and energy-intensive interventions. Its durability means less frequent replacement and lower cement consumption, which helps decrease CO₂ emissions – a major contributor to climate change. By conserving resources and reducing waste, self-healing concrete supports greener construction practices.

Technical Barriers and Cost Considerations

Despite its promise, self-healing concrete faces technical and economic hurdles. The initial cost is higher than conventional concrete, which can deter adoption in a cost-sensitive industry. There is also a lack of standardized testing methods and long-term performance data, making it difficult to guarantee consistent results and market credibility. Additionally, the efficiency of biological self-healing agents can be affected by the harsh alkaline environment of concrete, requiring further research to optimize performance.

Integration with Existing Facade Systems

Integrating this type of concrete into current facade systems presents practical challenges, including compatibility with other materials and construction methods. The absence of widespread demonstration projects and clear standards can make stakeholders hesitant to specify self-healing concrete in new designs. Overcoming these barriers will require continued innovation, industry collaboration, and robust case studies to build confidence in this transformative technology.

Autonomous Repair

Future-Proof Facades thanks to Concrete Innovation

Ongoing research into self-healing concrete is rapidly advancing, with new methods and materials emerging to enhance performance and scalability. Recent trends include the development of autonomous healing systems – such as capsule-based, vascular, and microbial approaches—that enable concrete to repair cracks without human intervention. Microbial healing, in particular, is gaining traction due to its sustainability and effectiveness. With bacteria like Bacillus subtilis it is demonstrating strong results in both laboratory and real-world applications. Chemical encapsulation and shape memory alloys are also being explored to extend healing capabilities and adapt to various environmental conditions.

As costs decrease and performance improves, the potential for widespread adoption in facade design grows. Self-healing concrete is already being piloted in infrastructure and commercial projects, with proven benefits such as extended lifespan, reduced maintenance, and lower carbon emissions. However, industry reluctance remains a barrier, often due to unfamiliarity with the technology or concerns about initial investment. Case studies demonstrate successful outcomes,. And as sustainability becomes a core priority, this innovative concrete is likely to become a standard material in facade engineering.

In conclusion self-healing concrete represents a transformative step for building envelopes, offering autonomous crack repair, enhanced durability, and significant sustainability gains. For facade engineers and architects, embracing these innovations means designing structures that are more resilient, cost-effective, and environmentally responsible – paving the way for the next generation of sustainable architecture

Useful links:

https://www.lidsen.com/journals/rpm/rpm-06-01-006

https://www.mdpi.com/2075-5309/14/4/961

https://www.fortunebusinessinsights.com/self-healing-concrete-market-109689

Case studies

Railway underpass, Rijen, NL (2024)

Construction company: Heijmans Infra

Heijmans Infra, in collaboration with ProRail, pioneered the use of self-healing concrete in a railway underpass pilot project in Rijen, the Netherlands. This innovative concrete incorporates bacteria and nutrients that activate upon exposure to oxygen and moisture, producing limestone to autonomously fill cracks. The project applied a mixture containing six kilograms of bacterial spores per cubic meter in a 25-meter basement wall beneath a tunnel entrance. By using this innovative concrete, Heijmans reduced horizontal reinforcement steel by 35%, leading to significant CO₂ emission savings. This marks the first project combining self-healing concrete with reduced reinforcement, enhancing waterproofness and extending the structure’s lifespan. The microbiological process, developed at TU Delft, demonstrates promising advances in sustainable and durable construction materials.

LUMC hospital, Leiden, NL

Self-healing concrete application: Basilisk

At LUMC Hospital in Leiden, hairline cracks (0.2 mm) were discovered in the concrete balconies, posing future durability risks due to potential moisture ingress and reinforcement corrosion. Traditional repair options like coatings were costly, required periodic reapplication, and altered the concrete’s appearance. Instead, the team chose Basilisk ER7, a bio-based self-healing concrete spray. This innovative solution penetrated the cracks and triggered limestone formation, sealing the cracks permanently without changing the surface look. The application was quick and odorless, treating 2,000 m² over seven floors in just two weeks. Results included 40% cost savings, 90% CO₂ reduction, and long-term protection of the balconies – demonstrating its practical benefits for sustainable building maintenance.