Acoustic comfort is a critical aspect of occupant well-being in today’s densely populated urban environments. Excessive noise from traffic, construction, and neighboring activities can negatively impact concentration, productivity, and overall health. Facade systems play a pivotal role in controlling the transmission of external noise into interior spaces. As buildings become more multifunctional and open, ensuring a quiet, comfortable indoor environment is increasingly essential for both residential and commercial spaces. In some regions (such as NYC) local building codes require laminated glazing to ensure acoustic comfort in new developments. These regulations are designed to mitigate external noise intrusion in areas exposed to high levels of urban noise. In this article, Facade Today explores how integrating sound-absorbing materials and innovative design strategies into modern facades can significantly reduce unwanted noise and contribute to a healthier, more productive indoor atmosphere.

Decoding Decibels

Key Metrics for Sound-Absorbing Facades

The building facade serves as a critical barrier between the bustling urban soundscape and the interior environment. Its effectiveness in controlling noise transmission depends on several design factors. These include the selection of materials, the configuration of layers, and the quality of construction. Multi-layered facades, such as double-skin or ventilated systems, create air gaps that dissipate sound energy and reduce its passage indoors. The integration of dense, non-porous materials – like concrete, masonry, or laminated glass – further limits the penetration of airborne noise. Additionally, the use of acoustic insulation within the facade cavity and the careful sealing of joints and penetrations are essential to prevent sound leaks. Elements such as acoustic glazing, absorptive panels, and decoupled framing systems can be tailored to target specific noise frequencies. They offer enhanced protection against both high- and low-frequency sounds.

Key Acoustic Performance Metrics

To ensure facades meet acoustic comfort requirements, engineers rely on standardized performance metrics:

Sound Transmission Class (STC): This rating quantifies a material or assembly’s ability to block airborne sound, particularly in the mid-frequency range typical of speech and urban noise.

Weighted Sound Reduction Index (Rw): Expressed in decibels (dB), Rw measures the overall sound insulation value of a building element, allowing for direct comparison between different facade systems.

Outdoor-Indoor Transmission Class (OITC): OITC evaluates a facade’s effectiveness against lower-frequency noise sources, such as traffic and heavy machinery, which are common in urban environments. Optimizing these metrics during the design phase enables facade engineers to deliver buildings that provide superior acoustic comfort, supporting occupant well-being and productivity.

Breaking the Sound Barrier

Next-Gen Materials for Quiet Interiors

The advancement of facade acoustics has led to a diverse range of innovative materials specifically engineered to enhance sound absorption and reduce noise transmission. Among these, acoustic panels and micro-perforated materials stand out for their versatility and effectiveness.

Acoustic Panels

Modern acoustic panels are fabricated from materials such as mineral wool, fiberglass, polyester fibers, or recycled cellulose. These panels are typically installed within the facade cavity or as part of rainscreen systems. Their porous structure enables them to trap and dissipate sound energy, significantly reducing reverberation and airborne noise.

Technical specifications:

- Sound Absorption Coefficient (αw): High-performance panels achieve αw values between 0.75 and 1.00, indicating excellent sound absorption across a broad frequency range.

- Thickness: Panels range from 25 mm to 100 mm, with thicker panels providing enhanced low-frequency absorption.

- Density: Common densities are 40–120 kg/m³, balancing mass and porosity for optimal performance.

- Fire Resistance: Many panels are classified as Euroclass A1 or A2-s1,d0 under EN 13501-1, ensuring minimal contribution to fire.

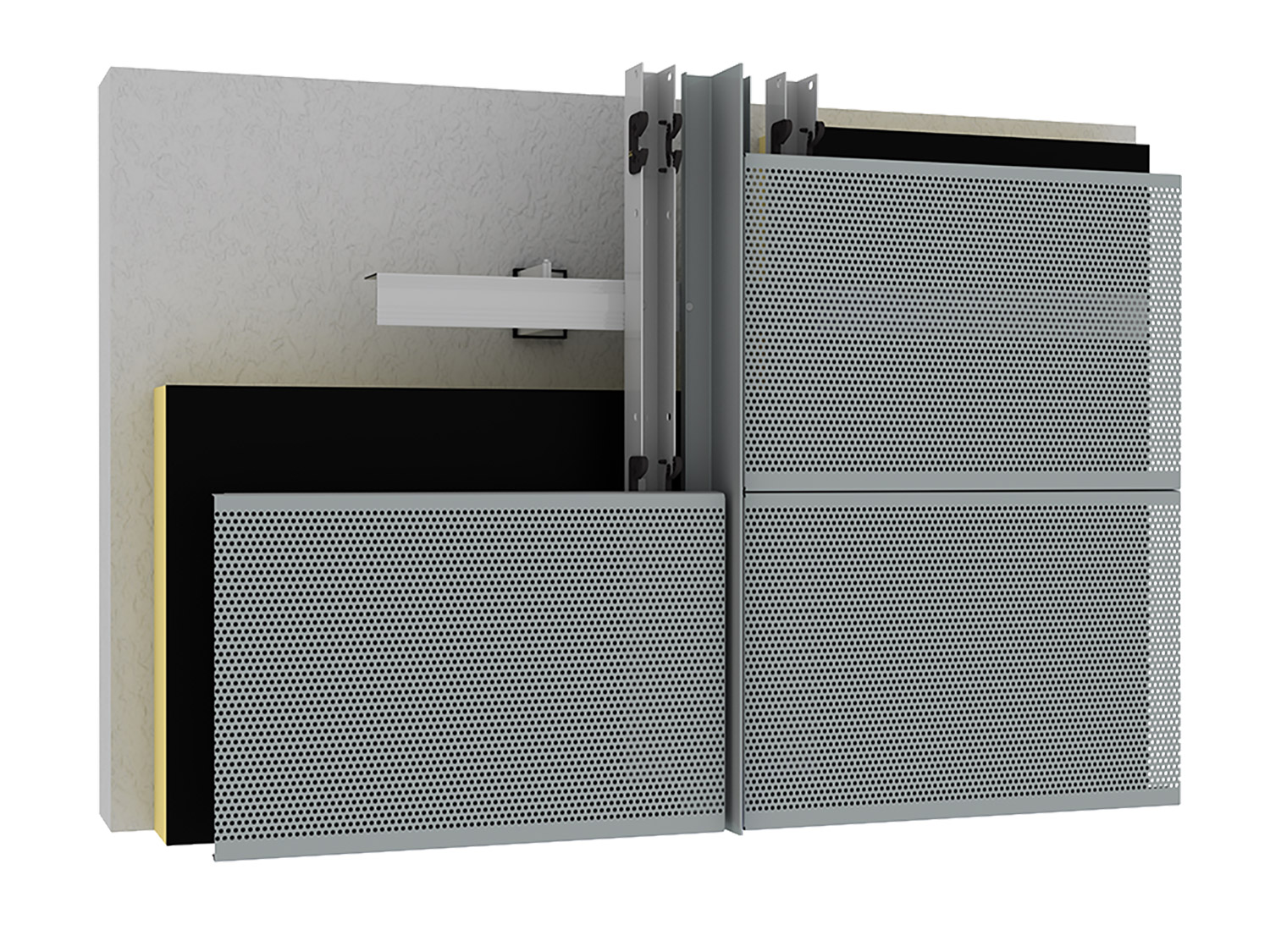

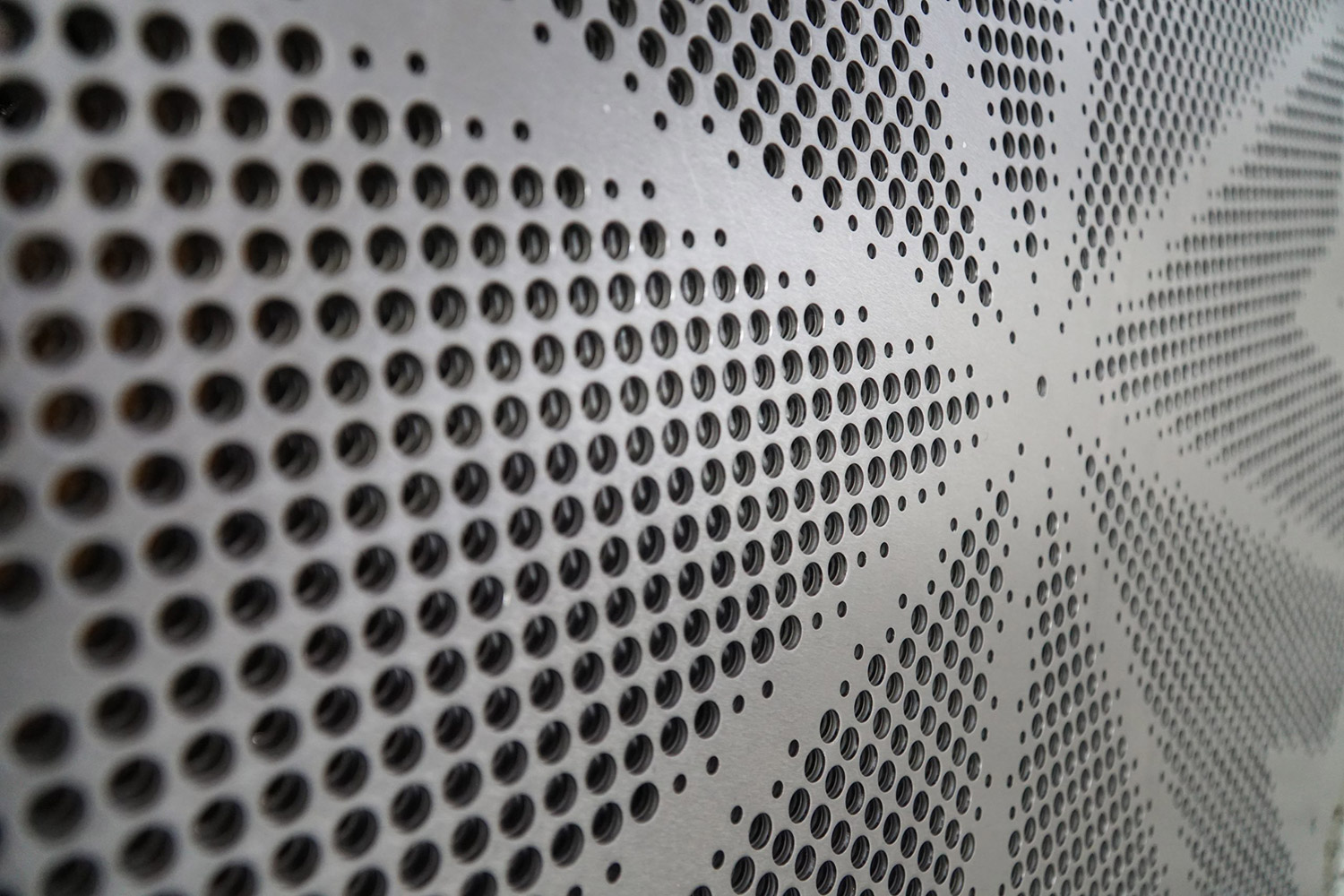

Micro-Perforated and Perforated Metal Panels

Micro-perforated panels, made from aluminum, steel, or composite materials, use thousands of tiny holes (typically 0.5–2 mm in diameter) to absorb sound via viscous losses in the air. When combined with an air gap and absorptive backing, these panels deliver effective broadband absorption while maintaining a sleek, durable exterior.

Technical specifications:

- Perforation Ratio: Effective panels have an open area of 10–20%, with hole diameters of 0.5–2 mm spaced at 2–5 mm centers.

- Panel Thickness: Ranges from 1.0 mm (aluminum) to 2.5 mm (steel), depending on structural and acoustic requirements.

- Back Cavity Depth: Optimal absorption is achieved with a cavity of 50–200 mm behind the panel, filled with mineral wool or similar material.

- Durability: Panels are often powder-coated or anodized for corrosion resistance, especially in exterior applications.

Composite and Bio-Based Materials

Emerging acoustic solutions include panels made from recycled PET, hemp, or mycelium-based composites. These materials offer sustainable alternatives with comparable absorption properties and are often used in projects targeting green building certifications.

Technical specifications:

- NRC (Noise Reduction Coefficient): Values of 0.70-0.95 are common for eco-friendly panels.

- VOC Emissions: Low-emission materials are preferred for indoor air quality, with certifications such as Greenguard or Blue Angel.

Role of Glazing and Window Systems

Glazing and window systems are critical elements in acoustic facade design, as they often represent the weakest point for sound insulation. Advances in glass technology and framing systems now enable high levels of acoustic protection without sacrificing daylight or views.

Laminated and Acoustic Glass

Laminated glass, comprising two or more panes bonded with a polyvinyl butyral (PVB) or acoustic interlayer, effectively dampens sound vibrations. Specialized acoustic interlayers further enhance performance by disrupting sound wave transmission.

Technical specifications:

- Rw (Weighted Sound Reduction Index): Standard double glazing achieves Rw values of 30-35 dB, while laminated acoustic glass can reach 40–45 dB or higher.

- Glass Thickness: Increasing pane thickness (e.g., 6 mm + 12 mm air gap + 8 mm) improves low-frequency attenuation.

- Interlayer Type: Acoustic PVB interlayers (e.g., SentryGlas® Acoustic) provide up to 3-5 dB additional reduction compared to standard PVB.

Triple Glazing and Asymmetric Configurations

Triple glazing, using three panes with varying thicknesses and air or gas-filled cavities, offers superior acoustic insulation. Asymmetric configurations – where pane thicknesses differ – help break up resonance and reduce transmission of specific frequencies.

Technical specifications:

- Configuration Example: 8 mm glass / 16 mm argon / 6 mm glass / 12 mm argon / 10 mm glass.

- Achievable Rw: 45-50 dB, suitable for high-noise environments such as urban centers or near airports.

Window Frames and Seals

The choice of frame material (aluminum, PVC, timber) and the quality of seals play a significant role in overall acoustic performance. Multi-chambered frames and double or triple gaskets minimize sound leakage.

Technical specifications:

- Frame Insulation: Multi-chambered PVC or thermally broken aluminum frames enhance both thermal and acoustic insulation.

- Seal Performance: Compression seals with dual or triple layers achieve better airtightness, contributing to higher Rw values for the window assembly.

Ventilated Acoustic Windows

For spaces requiring natural ventilation, acoustic trickle vents or ventilated window units incorporate internal baffles and absorptive linings to allow airflow while attenuating external noise.

Technical specifications:

- Dnew (Element Normalized Level Difference): Acoustic vents can provide Dnew values of 35-40 dB, maintaining comfort even with openable elements.

Future Trends

and The New Sound of Innovation

Smart Facades with Adaptive Acoustic Features

Building on the advanced materials and design strategies discussed earlier, the future of facade systems lies in their ability to actively respond to changing acoustic environments. Smart facades now incorporate embedded sensors and actuators that monitor noise levels in real time and adjust configurations accordingly. As described in the article, operable panels and dynamic shading devices are increasingly being adapted to shield interiors from peak noise events while maintaining ventilation and daylight. Integration with building management systems enables these facades to balance acoustic comfort, energy efficiency, and occupant preferences, transforming the building envelope into a truly responsive system.

Emerging Materials and Digital Design Tools

As highlighted in previous sections, innovations in material science are rapidly expanding the palette of sound-absorbing solutions. New high-performance composites, nanomaterials, and bio-based products – such as aerogel-infused panels and mycelium-based composites – are being explored for their outstanding acoustic and environmental properties. In parallel, parametric modeling tools and acoustic simulation software, empower architects and engineers to optimize facade design for targeted noise reduction. These technologies, building on the principles and materials detailed earlier, enable rapid prototyping and performance-based design. They ensure that acoustic objectives are met from concept through construction.

Conclusion

The Evolving Role of Facade Engineering in Acoustic Comfort

To stay ahead in acoustic facade design, designers and engineers should embrace adaptive and smart technologies that future-proof building performance. Selecting materials that offer both outstanding acoustic properties and sustainability benefits is increasingly important. Leveraging advanced digital tools for precise acoustic modeling and iterative design will further ensure optimal outcomes. This approach allows for effective integration of innovative solutions. Moreover, early collaboration with acoustic consultants is essential to seamlessly incorporate these strategies into the overall building concept. As a result, facades deliver both exceptional performance and user satisfaction.

Useful links:

https://www.sciencedirect.com/science/article/abs/pii/S0360132319302914

https://journals.sagepub.com/doi/10.1177/1351010X211034665

Case studies

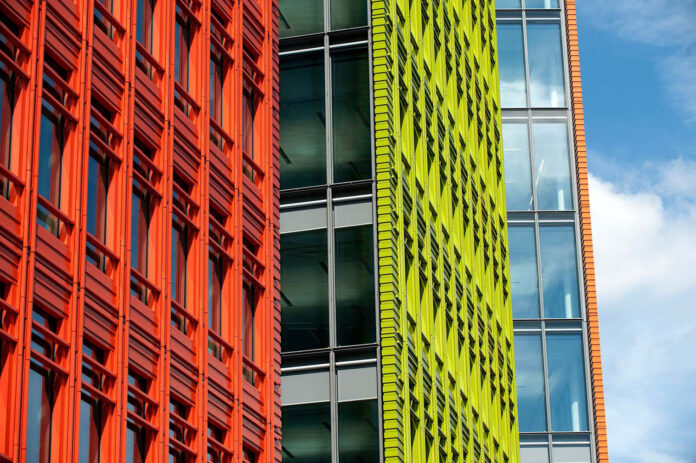

Central St. Giles Court / Renzo Piano + Fletcher Priest Architects

Architects: Renzo Piano Building Workshop (RPBW) + Fletcher Priest Architects

Acoustic simulations: Buro Happold Engineering

Central St. Giles Court stands out in London’s urban landscape for its vibrant, multi-faceted ceramic facade, designed by RPBW and Fletcher Priest Architects to balance aesthetics and acoustic comfort. The facade engineering, led by Schneider Fassaden, features curtain-type, ventilated terracotta panels and double-skin glazing. Acoustic performance was a key focus. Ground-floor surfaces facing the piazza incorporate absorptive materials to reduce noise intrusion from busy streets. Acoustic simulations haven been performed by Buro Happold Engineering. They demonstrated that even partial application of sound-absorbing panels on the lower facade significantly lowered sound pressure levels. This resulted in a more comfortable public space in the central courtyard. This project exemplifies how architectural form, materiality, and facade engineering can enhance both urban identity and acoustic quality.

LC Livin Residential Building, Lahnstein, Germany (2023)

Architects: MPLUS Architekten

Facade acoustic experts: Kalzip & Fraunhofer Institute for Building Physics

The LC Livin Residential Building in Lahnstein, completed in 2023, exemplifies innovative acoustic design in urban housing. Designed by MPLUS Architekten, the project addresses significant noise from a nearby railway. The façade engineering was developed in partnership with Kalzip GmbH, utilizing their FC system. Sound-absorbing expertise came from the Fraunhofer Institute for Building Physics (IBP). IBP collaborated on the design and testing of the perforated aluminum panels and specialized membranes. This tailored façade system achieves sound absorption between 6 and 20 dB. It is surpassing local noise reduction requirements, ensuring a quiet, comfortable environment for residents in a vibrant, heritage-rich setting.

As the Editor of FacadeToday.com, I merge my passion for Design, Architecture and Technologies with three decade of experience collaborating with entrepreneurs across many industries. My career has centered on fostering innovation, scaling business opportunities, and bridging gaps between technical experts, business developers, and creative visionaries. I thrive at the intersection of sustainable solutions, material advancements, and smart technologies, curating insights on themes like energy-efficient facades, smart tech, and advanced manufacturing. With a commitment to lifelong learning, I aim to empower architects and facade engineers by translating innovations into actionable knowledge, driving the industry forward through purposeful connectivity and cutting-edge practices.